How Precious Metals Recycling Companies Leverage 3D Scanning

The Green Guide to Precious Metal Reclamation

More than $60 billion in precious metals end up in e-waste every year—did you realize that? This staggering figure underlines the critical role of precious metal recycling. It’s not just good for our economy but also for the environment. Reclaiming gold, silver, platinum, and palladium helps lower pollution and preserve what’s left of our natural resources.

Companies like Dongsheng Metal Trading are leading the charge towards sustainability. They make sure those precious metals get reused rather than landfilled. That precious metals recycling strategy underpins green recycling and long-term sustainability.

Core Insights

- Over $60 billion in precious metals is disposed of in electronic waste annually.

- Precious metal recycling reduces environmental impact and conserves resources.

- Valuable metals include gold, silver, platinum, and palladium.

- Eco-friendly recycling practices are vital for sustainable development.

- Recycling experts like Dongsheng Metal Trading lead the industry.

Exploring Precious Metals and Their Worth

Naturally scarce metallic elements called precious metals draw interest from industries and investors. Gold, silver, platinum, and palladium stand out for their distinct qualities. They offer conductivity, resist corrosion, and occur in limited supply. The extraction and processing of these metals require considerable resources, underscoring the importance of recycling precious metals.

Intrinsic qualities and demand in the marketplace determine precious metals’ worth. Recovering metals is key to keeping the supply chain alive. It lowers the ecological damage from mining. Advanced recycling can bring metals back to their initial quality. This preserves finite resources while yielding economic benefits.

What are Precious Metals?

Unique features make precious metals ideal for many uses. Economic value stems from their scarcity and innate qualities. Notable examples are:

- Gold: Prized for its shine and tarnish-proof nature.

- Silver: Known for flexible uses and excellent conductivity.

- Platinum: Esteemed for its toughness and catalyst role.

- Pd: On the rise in automotive and tech industries.

Reasons to Recycle Precious Metals

The practice of recycling precious metals has emerged as a vital component for sustainability. It preserves resources and lessens the environmental cost of mining. Here are some benefits:

- Lessening of habitat destruction from mining.

- Lower energy consumption compared to extracting new metals from the earth.

- Contribution to a circular economy by reintroducing materials into production cycles.

- Potential for financial gains through the reclaiming of high-value materials.

Why Precious Metal Recycling Matters

Metal recycling brings both green and economic gains. Pointing out these perks shows how to shrink our eco-impact. Plus, it spurs economic development and steadiness.

Green Benefits

Recycling metals yields major environmental perks. When we recover metals from e-waste and scrap, landfill volume drops. That cuts new mining needs and saves resources.

This approach minimizes the harmful effects of mining, such as habitat destruction and pollution. A focus on metal recovery moves us toward real sustainability.

Economic Advantages

Economic upsides of recycling stand out equally. Using reclaimed metals trims manufacturing budgets. It lets businesses choose reclaimed over freshly mined metals.

This shift creates jobs in recycling facilities and boosts market stability as demand for recycled metals grows. By leveraging these economic advantages, businesses can improve their profitability. They further support a cleaner economy.

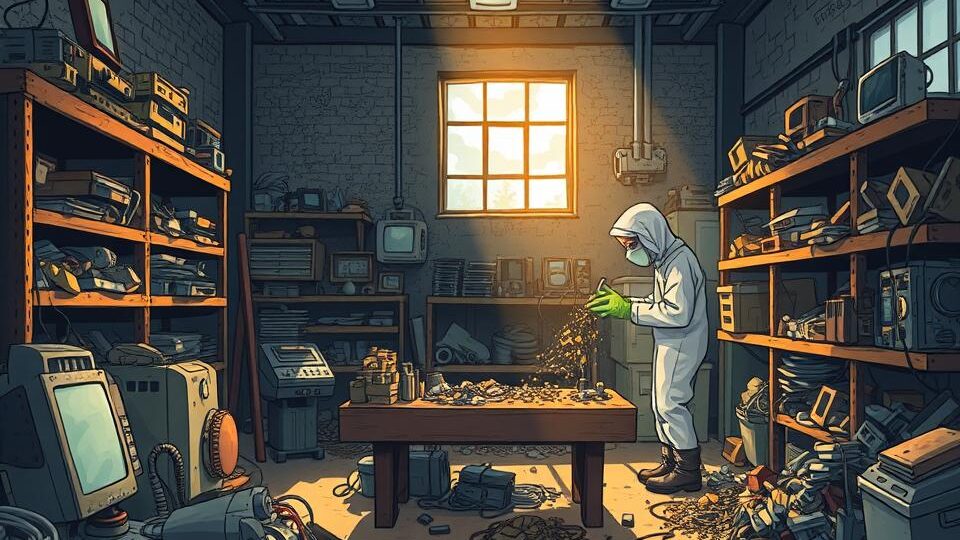

The Precious Metal Recycling Process

Metal recycling demands a multi-stage process to optimize recovery. It starts with collecting metals from various sources like discarded electronics, jewelry, and industrial scraps. Next comes sorting, cleaning, and testing to assess metal content and worth.

Recycling Workflow

This systematic approach is vital for effective metal recovery. Every phase aims to maximize precious-metal returns. Sorting divides metals by kind and grade. Cleaning strips away impurities that impede extraction. Chemical analysis pinpoints metal levels to drive technique decisions.

Recycling Techniques Used

Advanced recycling techniques are employed to achieve high metal recovery rates. Thermal reduction applies intense heat to isolate metals. Smelting and chemical baths extract and purify metals. Recyclers like Dongsheng Metal Trading employ these approaches to improve yields and returns.

Which Precious Metals Are Recyclable

Recycling is vital for the environment and for recovering valuable materials. A host of precious metals are recyclable, aiding markets and ecosystems. Knowing which metals are recyclable helps individuals and firms.

Key Precious Metals

Gold, silver, and platinum are well-known precious metals. You’ll see them in rings, currency, and industrial parts. Recycling gold is common due to its high value and demand. Silver recovery matters too, thanks to its role in imaging, tech, and solar.

Platinum, while rarer, finds value in catalytic converters.

Electronics Precious Metals

Electronics scrap contains metals ripe for recovery. Devices such as phones and computers hold palladium and indium. Recovering such metals diminishes e-waste and yields vital materials.

The need to recycle these metals is critical. Sectors strive to cut waste and boost recycling efficiency.

Industries that Benefit from Precious Metal Recycling

Recycling precious metals supports industries by providing efficient, green resource supply. Device manufacturing in electronics profits hugely from recovered metals. The aerospace and medical fields use precious metals in essential applications. Looking at their recycling practices shows green and financial gains.

Electronics Industry

Electronics spearheads recovery, given the metal content in phones and PCs. Quick device turnover spawns more electronic scrap. Hence, recovering metals like gold, silver, and palladium is crucial. It preserves nature and lowers mining-driven CO₂ emissions.

Firms ramp up recycling to hit sustainability targets. That change bolsters resource saving and ecosafety.

Aerospace & Medical

Metal recovery is key in aerospace and medical sectors where metals are in vital parts. Alloys prized for strength and anti-corrosion make up flight and medical components. Recycling these metals can significantly lower material costs and comply with environmental regulations.

They recognize that recycling offsets material scarcity. It also enhances operational efficiency, making recycling a key strategy for sustainability.

How to Choose a Metal Recycler

Locating reliable recycling partners ensures great results. It’s wise to ask important questions to understand their operations. Pricing models and processes make a big difference. Service comparisons help you pick the best recycler.

What to Ask a Recycler

- Can you share your precious-metal recovery accreditations?

- Can you explain your processing methods for different metals?

- What are your recovery rates for various precious metals?

- Can you detail your fees and any surcharges?

- Do you have client testimonials or references?

Service & Price Comparison

You must evaluate services side-by-side to pick the right recycler. Create a table to compare key factors such as:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

Side-by-side comparisons help pinpoint the ideal recycler. It guarantees maximum value and compliance.

Recycling Precious Metals: A Green Guide

Grasping recycler workflows is essential for metal recovery. They handle all stages, from gathering to final refining. This ensures maximum efficiency and value from metals.

Recycler Operations

They apply high-tech processes—testing, sorting, refining—to recover metals. First, they gather scrap from multiple origins. Then, they use sophisticated techniques to separate different metals. Finally, they refine each batch to recover gold, silver, platinum, etc.

This process not only maximizes resource recovery but also supports eco-friendly practices. It’s fundamental to building a sustainable future.

Selecting Your Ideal Recycler

You’ll want to weigh several factors in your choice. Start with their sustainability track record. Now more than ever, green commitment is crucial. Also, examine if they handle everything or only certain stages.

Your budget will influence your choice. Gather price quotes for side-by-side comparisons. Firms such as Dongsheng Metal Trading tailor services to each sector. They are a reliable choice for specific recycling needs.

Types of Recycling Facilities

Metal recycling is a critical sector for sustainable practices and waste management. There are specialized centers for different metals and materials. Knowing the facility landscape helps you connect with the right partner. That supports firms and ecosystems alike.

Types of Facilities Available

Facilities differ greatly in their focus and processes. Certain centers specialize in high-value metals; others take general scrap. Common examples include:

- Metal Scrap Yards: Typically focus on general metal waste, including ferrous and non-ferrous metals.

- Specialized firms recover gold, silver, and platinum with advanced refining.

- E-Waste Recycling Centers: Specialize in recovering metals from discarded electronics, capitalizing on the valuable components often found in these devices.

Facility Access Factors

Proximity to recyclers cuts logistical hurdles. Businesses must consider the logistics of transporting materials. Key access factors include:

| Factor | Description |

|---|---|

| Proximity | Facilities located nearer to businesses minimize transportation costs and time. |

| Partnerships | Having established relationships with local recyclers can enhance efficiency in recycling processes. |

| Service Range | Awareness of service menus aids in picking the right center. |

Choosing appropriate centers and easy access drives recovery efficiency.

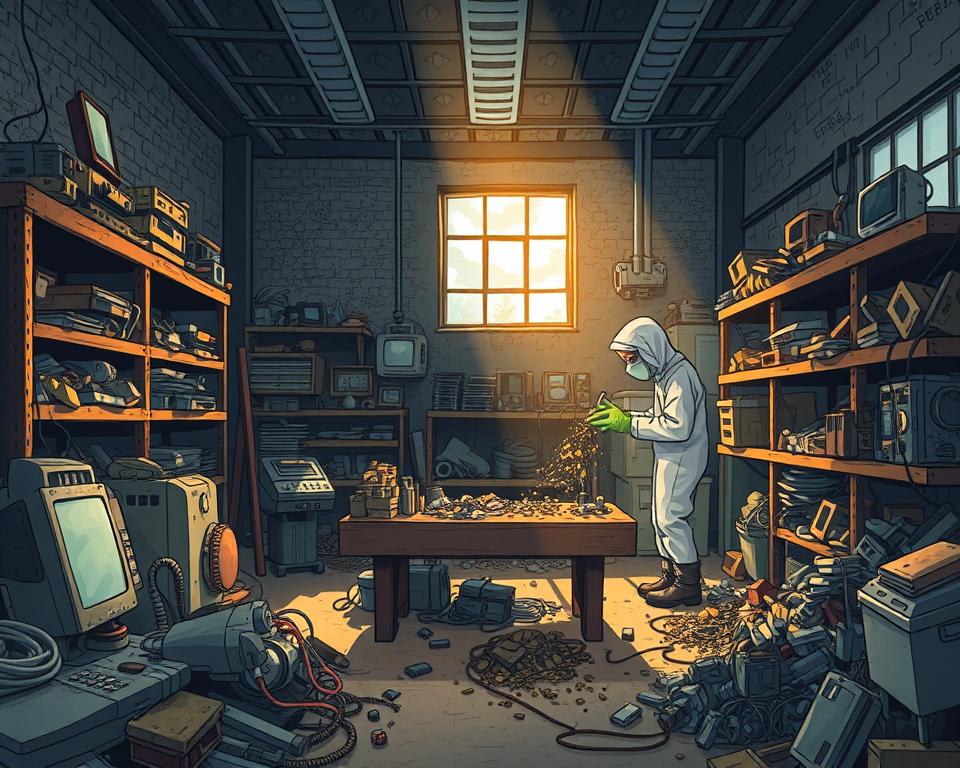

Electronic Waste Recycling and Precious Metals

Electronic waste is a pressing issue in today’s world, causing environmental harm. Old gadgets hide valuable metals ripe for recovery. This highlights the importance of seeing e-waste as a valuable resource.

How Electronics Contain Precious Metals

Many electronic devices hold small amounts of precious metals like gold, silver, and palladium. These metals are found in various parts:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

Even everyday items like smartphones, laptops, and TVs are filled with these metals. With recycling, we can efficiently recover and reuse them.

The Importance of E-Waste Recycling

E-waste recycling is vital for both environmental protection and resource recovery. It reduces landfill waste and saves natural resources. The benefits of recycling e-waste metals are clear:

- It cuts ecological hazards from poor e-waste handling

- It reduces CO₂ output via green recycling methods

- It supports the circular economy by recycling materials back into production

Encouraging electronic recycling promotes sustainable resource management. It’s essential for the well-being of future generations.

The Future of Precious Metal Recycling

Metal recycling is evolving, spurred by tech advances and green initiatives. As the need to conserve resources grows, major players in recycling are adapting. By integrating novel processes, they pave the way forward.

Eco-Friendly Recycling Innovations

Modern green recycling strives to cut waste and eco-damage. Firms now use bio-packaging and low-energy methods. Such moves match worldwide green goals and nudge industries to be more eco-responsible.

New Metal Recovery Tech

New methods in recovery enhance recycling performance. New technologies, such as automated sorting and hydrometallurgical extraction, enhance recovery rates. These innovations not only increase resource extraction but also reduce environmental impact, marking a significant step forward in recycling precious metals.

Starting a Precious Metal Recycling Venture

Starting a precious metal recycling business demands meticulous planning and a deep grasp of operational and market dynamics. Founders need a roadmap, regulatory know-how, and solid groundwork. Key tasks include market studies and pinpointing customer segments. Also, obtaining necessary permits and understanding legal aspects is vital for sustained success.

Steps to Establishing a Business

Setting up a precious metal recycling venture requires several essential steps:

- Conduct market research to understand needs and rivals.

- Draft a strategy blueprint covering targets and methods.

- Acquire suitable recycling equipment that meets your operational needs.

- Secure funding through loans or investments.

- Get all required permits and licenses.

- Launch marketing to attract clientele.

Legal Considerations and Certifications

Knowing regulatory requirements is vital for a recycling startup. Adherence to environmental regulations ensures your operation is safe and sustainable. Key considerations include:

- Securing business certification from relevant authorities.

- Complying with local, state, and federal regulations on waste disposal and recycling.

- Training staff in safety protocols and best practices.

The Bottom Line

Precious metal recycling is essential for preserving natural resources and improving environmental health. It empowers all of us to reduce environmental harm from waste. The recovered metals reduce mining needs and boost the economy by creating jobs in recycling.

Metal recovery delivers both eco and economic upsides. Partnering with companies like Dongsheng Metal Trading ensures a commitment to eco-friendly practices. Such alliances reinforce the circular economy for all stakeholders.

Our path to sustainability relies on united metal recovery initiatives. Increased awareness builds a culture of green consumption and care. Embracing these steps helps today and protects tomorrow’s world.